Composite fabric is a new type of material that is bonded by one or more layers of textile materials, mesh fabric, non-woven materials and other functional materials. It is suitable for sofas, clothing, other textiles and industrial materials, such as wallcoverings. It is one of the indispensable fabrics in people's home life. Composite fabrics are made of microfibers in specific textile processing and unique dyeing and finishing processes, and then processed by "composite" equipment. The English of the composite fabric is: "Lamination Fabric" and "Soft Shell Fabric" Because the composite fabric uses microfiber, the fabric has a high cleaning ability, that is, decontamination ability.

1. Common compounds:

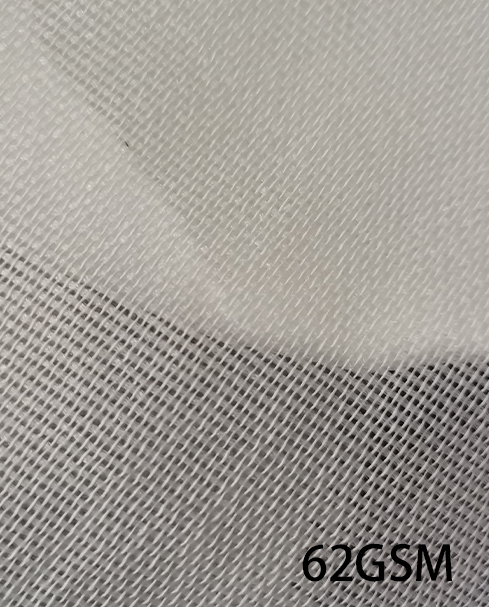

The composite fabric applies "new synthetic fiber" high technology and new materials, and has many excellent properties (compared with ordinary synthetic fibers), such as the performance of the fabric is clean, delicate, elegant, warm, the appearance of the fabric is plump, windproof, breathable. It has a certain waterproof function, and its main features are warmth retention and good breathability.

Another feature of the fabric is: good abrasion resistance, microfiber fabric is soft to the touch, breathable and moisture-permeable, so it has obvious advantages in touch and physiological comfort, while microfiber fabric has poor wrinkle resistance (This is because the fiber is soft. The elastic recovery after wrinkling is poor); in order to overcome this shortcoming, a "composite" process is adopted, which greatly improves the shortcoming of poor wrinkle resistance of microfiber fabrics. Composite fabrics are popular outerwear fabrics in Europe and America.

2.Classification of composite fabrics:

2-1. Woven fabric and knitted fabric compound

2-2. Knitted fabric and knitted fabric composite

2-3. Woven fabric and woven backing fabric composite

Sports and leisure clothing uses knitted fabrics and composite knitted fabrics, which have the effect of woven fabrics and have good elasticity. Therefore, in the eyes of consumers of this type of clothing, it is still relatively popular with the public.

3. Ordinary composite fabric:

The fabric and the lining are bonded by adhesive to improve the texture of the fabric, which is suitable for the simplification and large-scale production of garment processing.

4. Functional composite fabrics:

The composite fabric has special functions such as waterproof and moisture permeability, radiation resistance, washing resistance and wear resistance.

5. Process flow:

There are six kinds of composite technologies that are popular in the world, which are hot sol powder spraying composite technology, hot sol pastes point composite technology, hot sol powder spray composite technology, hot sol double-point composite technology, polyurethane spray composite technology, and polyurethane fabric composite technology. The roller coating lamination process is a relatively new fabric developed in the market. In short, it is a composite of two fabrics. The more common fit in the past was the fit of suede fabric and wool, but now any fabric can compound together.

Every batch of composite fabric must be effectively maintained. The reverse side fabric is first laminated (the film is a transparent material similar to nylon film), chemically bonded, and then maintained. The longer the maintenance time, the better the adhesion fastness to the fabric and the fusion of the adhesive. Generally, domestic glue needs three days of maintenance, and imported glue needs more than five days. The length of time the adhesive takes to fully bond between the fabric and the film also affects subsequent adhesion to the front fabric.

Ordinary composite gluing should pay attention to maintaining a certain temperature and humidity in the room, and let the glue blend naturally.